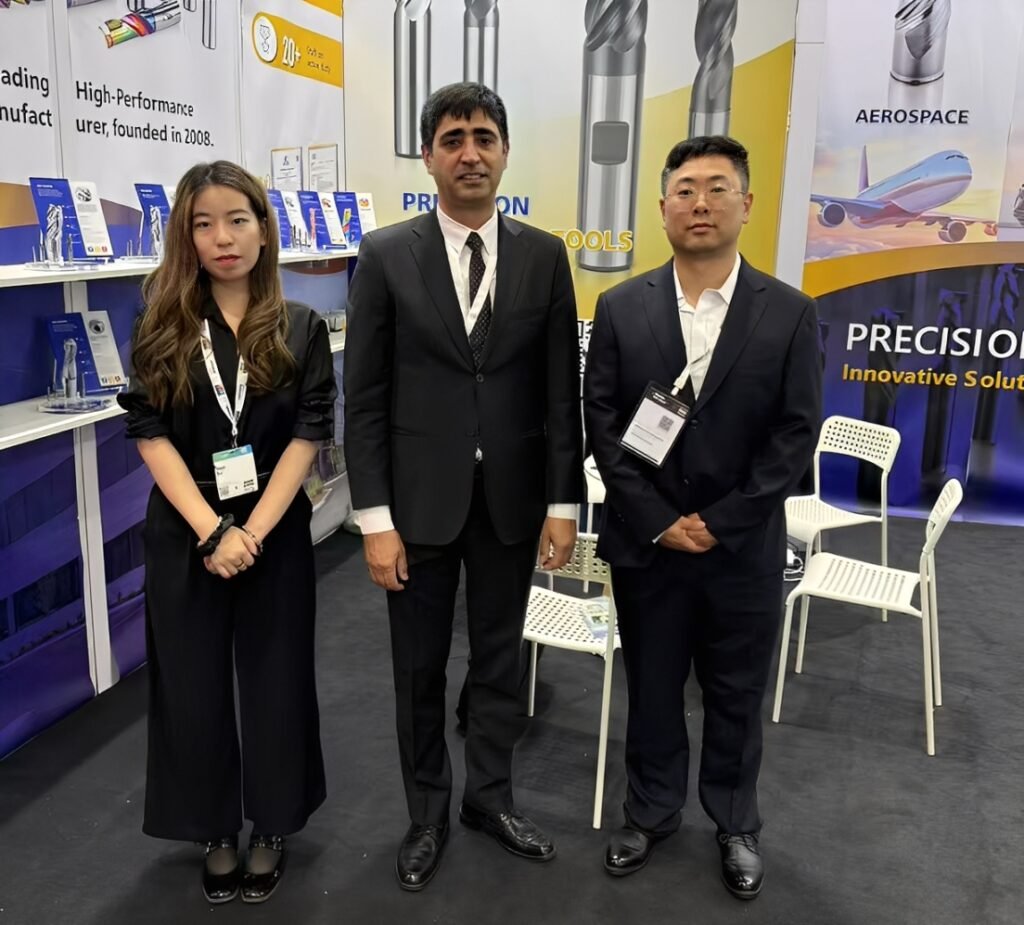

Precision Tools for the American Market – M9 PRO End Mills DB Series Drills

20 years of industry experience

Technical Highlights

Accuracy, innovation, and performance in inch-size tools

Ultra-fine carbide substrate for superior toughness

Advanced TiAlN coating for long tool life

Optimized geometry for high-speed machining

American inch standard compliance

Core Products

M9 PRO End Mills

High-performance inch end mills for steel, stainless steel, and aluminum.

DB Series Drills

Precision carbide drills with high penetration rate and stable chip evacuation.

Custom Tooling

Non-standard tools for special

applications.

Why Choose HNCarbide

High level quality, tailored for U.S. standards

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Factory-direct pricing

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Fast global shipping

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

Dedicated technical support

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Ut elit tellus, luctus nec ullamcorper mattis, pulvinar dapibus leo.

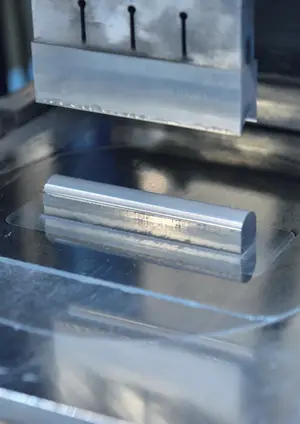

Production Process

Raw Material Selection

01

High-quality high-speed steel (HSS) is selected as the raw material for taps, ensuring good wear resistance and toughness.

Rod Cutting and Shaping

02

Thread Cutting

03

Precision cutting processes are used to cut the threads on the tap using CNC machines or specialized thread grinders, ensuring thread accuracy and sharpness.

Heat Treatment

04

Surface Treatment

05

Taps are coated with materials like TiN or TiAlN based on requirements, improving wear resistance, reducing friction, and extending tool life.

Quality Inspection and Packaging

06

How We Can Help You

Easy Procurement

By simplifying a single process for finding all the products that customers need, we make procurement easier.

Highest Standards

With in-house manufacturing, we meet customer's needs while adhering to quality compliances and international standards.

Direct Factorie

With products exported to 50+ countries, we offer high-quality, cost-effective tools, ensuring swift delivery and comprehensive technical support.

One-Stop Solution

Focusing on cutting tools for over 15years and still gose on, owning worldwide customers mainly from UK, France, Italy, Spain, Mexico…

Contact Us

Get in Touch with Us

Location

yuefeng load,zhangjiagang suzhou,jiangsu,China